Abrasive blasting won’t remove oil and grease – it just smears them over the surface, causing premature coatings failure. Visible deposits of oil, grease and dirt must be spot cleaned prior to abrasive blast cleaning. SP 1 is a prerequisite to the other SSPC abrasive blasting specifications.

The standards specify numerous methods for solvent cleaning. The most common method – and the least effective – is washing with soap, water and a rag. A dirty rag will also smear grease and oil: care must be taken to wipe, fold, repeat, and replace often. For large surfaces, pressure washing with soapy water is recommended, although soap residue will inhibit coating adhesion and should be rinsed off.

![]() Loosely adhering material: 100%

Loosely adhering material: 100% ![]() Tightly adhering material: 100%

Tightly adhering material: 100% ![]() Stains, streaks, shadows: 100%

Stains, streaks, shadows: 100%

AKA - Light Blast Cleaning, sweep blast

Brush Off is specified to remove loose rust, mill scale and coatings, and uniformly roughen up a surface in preparation for a new coat. Tightly-adherent materials are permitted to remain.

Brush Off is specified where the expected life of the coating is short, such as ship hull antifouling, or in mild atmospheres and non-corrosive service environments, such as the exterior of a tank, in a rural location.

![]() Loosely adhering material: 0%

Loosely adhering material: 0% ![]() Tightly adhering material: 100%

Tightly adhering material: 100% ![]() Stains, streaks, shadows: 100%

Stains, streaks, shadows: 100%

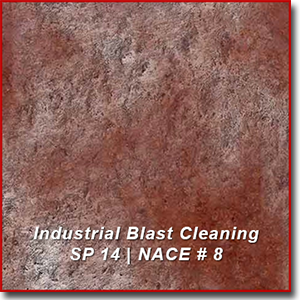

Industrial Blast Cleaning specifies that 90% of the tightly-adhered matter must go. Shadows, streaks and stains from rust, mill scale and old coatings are allowed on 100% of the surface.

Industrial is specified for conditions when the existing coating is thin, well-adherent and compatible with new coating. It is the most recent abrasive blasting standard, and not widely specified. ISO has no corresponding specification.

![]() Loosely adhering material: 0%

Loosely adhering material: 0% ![]() Tightly adhering material: 10%

Tightly adhering material: 10% ![]() Stains, streaks, shadows: 100%

Stains, streaks, shadows: 100%

AKA - Thorough blast cleaning

Commercial Blast Cleaning specifies that all tightly-adhering matter must go. Shadows, streaks and stains can remain on up to 33% of the surface.

Commercial is specified when a high, but not perfect, degree of cleanliness is warranted. It’s common for repainting products that serve in non-corrosive environments and atmospheres, such as tanks and bridges.

![]() Loosely adhering material: 0%

Loosely adhering material: 0% ![]() Tightly adhering material: 0%

Tightly adhering material: 0% ![]() Stains, streaks, shadows: 33%

Stains, streaks, shadows: 33%

AKA - Very thorough blast cleaning

Near White Blast Cleaning specifies that shadows, streaks and stains must be limited to 5% of the surface area. Near White is specified when the added benefit of blasting to White Metal doesn’t justify the added expense.

Near White is typically specified for high performance coatings over steel exposed to severe environmental conditions, such as chemical spills and fumes, high humidity, and proximity to salt water. It is commonly specified for off-shore platforms, shipyards and other marine environments.

![]() Loosely adhering material: 0%

Loosely adhering material: 0% ![]() Tightly adhering material: 0%

Tightly adhering material: 0% ![]() Stains, streaks, shadows: SP 10-5%, SA 2.5-15%

Stains, streaks, shadows: SP 10-5%, SA 2.5-15%

AKA - Blast Clean to Visibly Clean Steel

![]() Loosely adhering material: 0%

Loosely adhering material: 0% ![]() Tightly adhering material: 0%

Tightly adhering material: 0% ![]() Stains, streaks, shadows: 0%

Stains, streaks, shadows: 0%

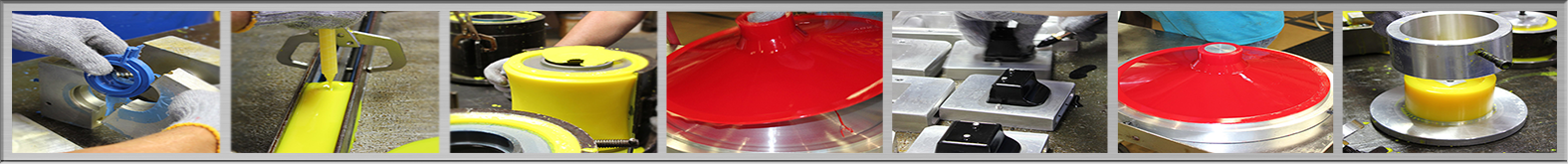

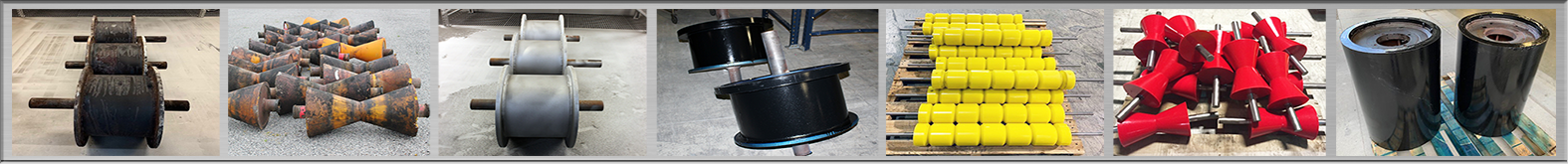

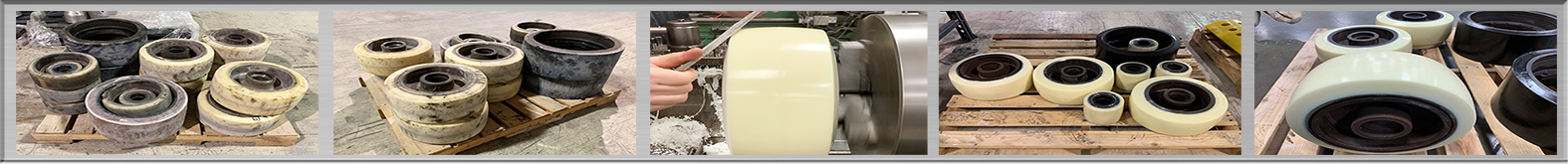

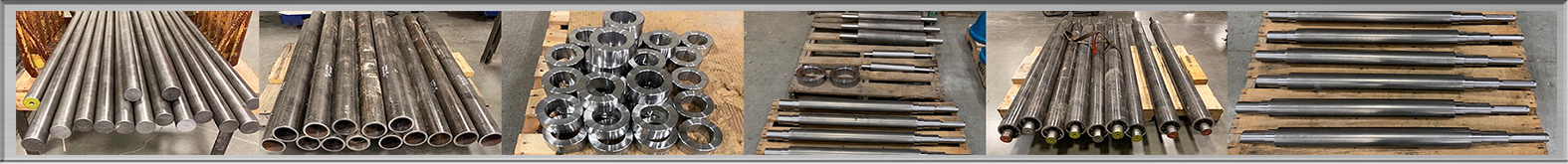

ESI is Your Custom Urethane Cast & Rebuild Specialists

V-Rollers ▪ Wheels ▪ Castors ▪ Sheaves ▪ Conveyor Rollers ▪ Large Turning Rollers

Elastomer Specialties, Inc. 2210 S Highway 69, Wagoner, OK 74467 Ph: 918-485-0276 Fax: 918-485-0253