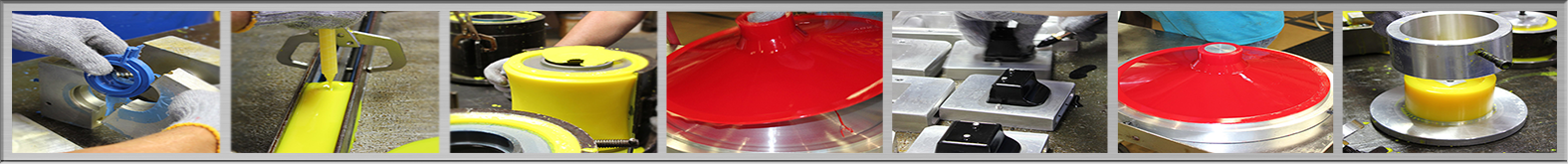

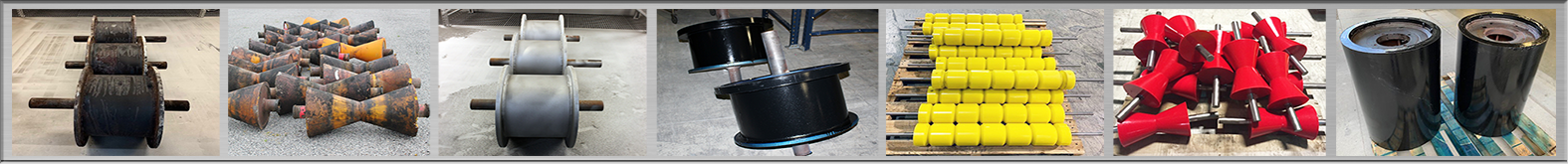

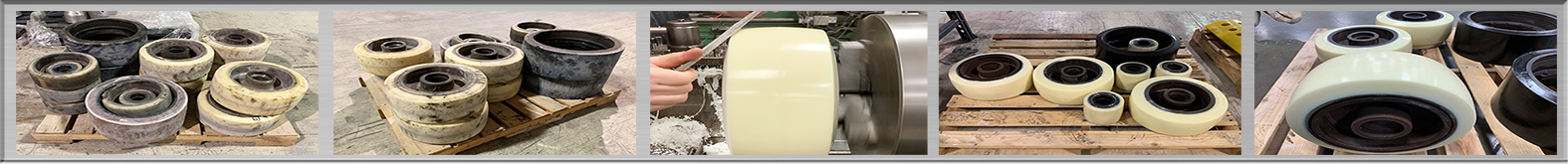

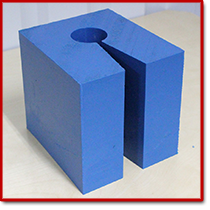

Custom Cast & Molded Urethane Products

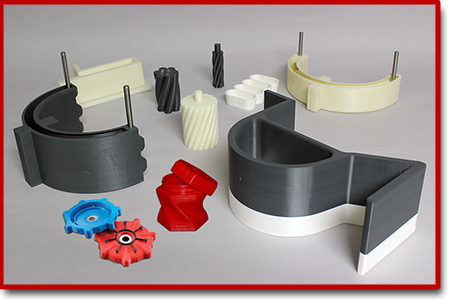

Our typical applications include manufacturing for conceptual models, visual analysis, low-volume production molds as well as engineering evaluations.

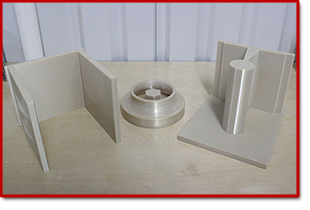

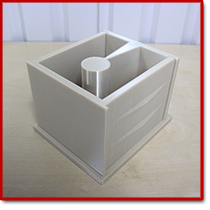

In order to offer our customers the best service possible, we chose two different 3D printer models. The FORTUS 250MC is our smallest machine with an operation build-size platform of 10"W x 10"D x 12"H. It is primarily used for smaller projects designed for visual analysis and conceptual models. The material used most frequently for these projects is an ABS product which keeps material cost at a minimum. When it comes to much larger projects ESI decided to incorporate the FORTUS 900MC. Both machines are made by STRATASYS. The 900MC offers a build-size platform of 24"D x 36"W x 36"H.Our Fortus 900MC is currently set up to operate with 4 separate materials,

ULTEM 9085, POLYCARBONATE, ASA and NYLON 12 CARBON FIBER. The 900MC

is by far the most versatile of the two machines and can build large scale parts or molds.

A temperature-controlled head, located inside a closed cabinet, extrudes thermoplastic material in layers, similar to how a hot glue gun extrudes melted beads of glue. Layering of this material produces parts with a very complex geometry that cannot be obtained by traditional methods of production.

In today's ever growing fast pace industry you will find FDM technology being utilized by engineers, designers and manufacturers on a daily basis.

In today's ever growing fast pace industry you will find FDM technology being utilized by engineers, designers and manufacturers on a daily basis.

If you or your company is looking to produce parts, a product mold or prototype from your 3D CAD file without the time and cost associated with machining, tooling and outsourcing then Elastomer Specialties can provide you with what you are looking for.

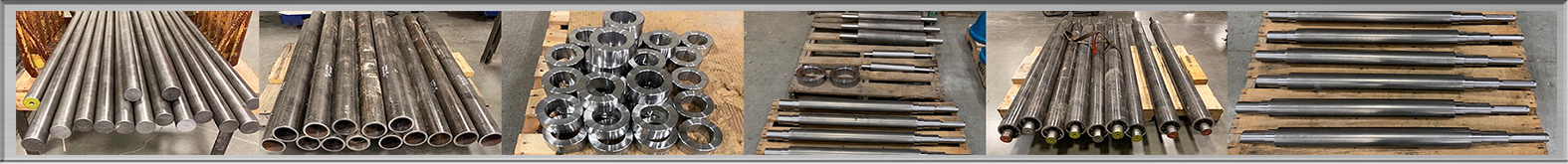

If you decide to eventually go into high volume part production, we also have that capability.At ESI, no outsourcing is necessary! We are a 'ONE STOP SHOP' and can take your project from beginning to end in the shortest amount of time possible.

There are many choices that need to be addressed before you can order a 3D printed part or prototype.

There are many choices that need to be addressed before you can order a 3D printed part or prototype.

It is helpful to have a STL file. STL is the format used by most 3D printers. If you do not have a STL file, we may be able to create one for you. We have several ways to create a STL file:

It is helpful to have a STL file. STL is the format used by most 3D printers. If you do not have a STL file, we may be able to create one for you. We have several ways to create a STL file:

Innovators of Molded Polyurethane and Hybrid Polyurea Technology!

Elastomer Specialties, Inc. 2210 S Highway 69, Wagoner, OK 74467 Ph: 918-485-0276 | 800-786-4244 Fax: 918-485-0253