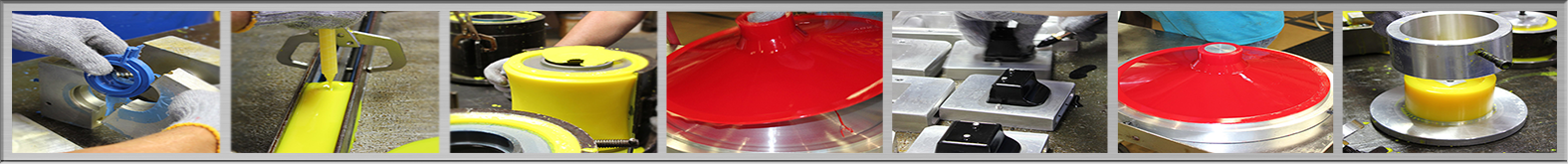

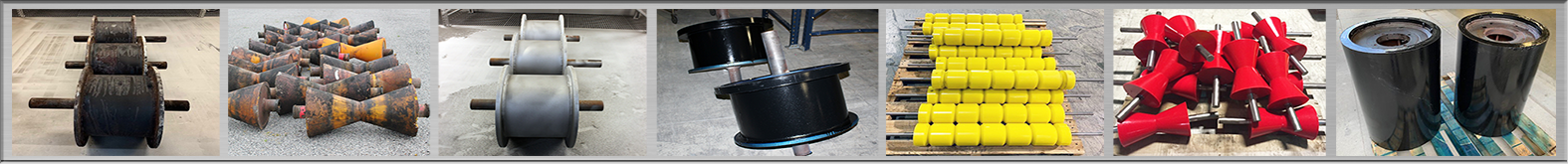

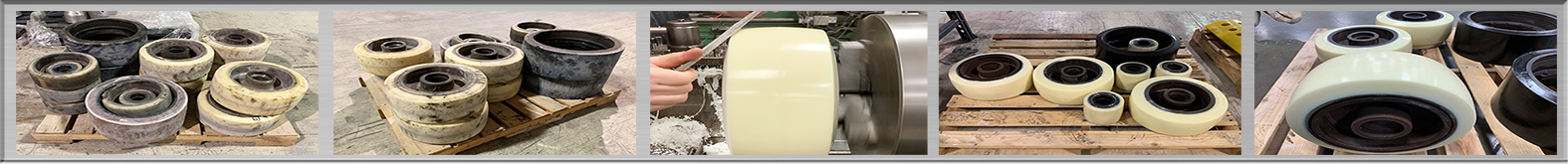

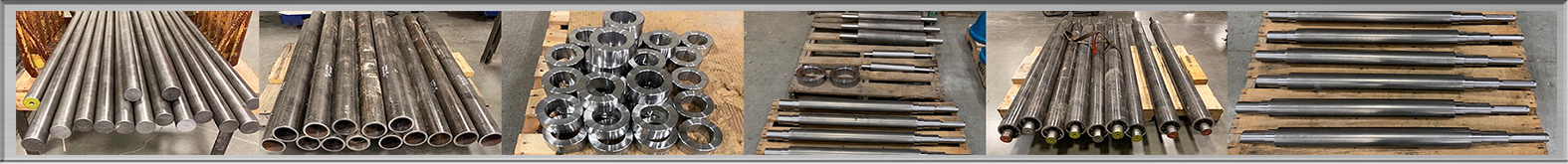

Custom Cast & Molded Urethane Products

Polyurethanes are formed by reacting a polyol (an alcohol with more than two reactive hydroxyl groups per molecule) with a diisocyanate or a polymeric isocyanate in the presence of suitable catalysts and additives. Because a variety of diisocyanates and a wide range of polyols can be used to produce polyurethane, a broad spectrum of materials can be produced to meet the needs of specific applications.

It does not matter where you look, you are likely to find polyurethanes. Polyurethanes can be found in mattresses, couches, insulation, liquid coatings and paints, tough elastomers such as roller blade wheels, soft flexible foam toys, some elastic fibers and many other places and applications.

Content provided by: https://polyurethane.americanchemistry.com/Introduction-to-Polyurethanes/

The origin of polyurethane dates back to the beginning of World War II, when it was first developed as a replacement for rubber. The versatility of this new organic polymer and its ability to substitute for scarce materials spurred numerous applications. During World War II, polyurethane coatings were used for the impregnation of paper and the manufacture of mustard gas resistant garments, high-gloss airplane finishes and chemical and corrosion-resistant coatings to protect metal, wood and masonry.

By the end of the war, polyurethane coatings were being manufactured and used on an industrial scale and could be custom formulated for specific applications. By the mid-50's polyurethanes could be found in coatings and adhesives, elastomers and rigid foams. It was not until the late-50's that comfortable cushioning flexible foams were commercially available. With the development of a low-cost polyether polyol, flexible foams opened the door to the upholstery and automotive applications we know today.Formulations, additives and processing techniques continue to be developed, such as reinforced and structural moldings for exterior automotive parts and one-component systems. Today, polyurethanes can be found in virtually everything we touch - desks, chairs, cars, clothes, footwear, appliances, beds as well as the insulation in our walls and roof and moldings on our homes.

Content provided by: https://polyurethane.americanchemistry.com/History/

Flexible polyurethane foam accounts for about 30 percent of the entire North American polyurethane market and is used largely for bedding, furniture and in the automotive industry.

According to the U.S. Department of Energy, heating and cooling account for about 56 percent of the energy used in a typical U.S. home, making it the largest energy expense for most homes. To maintain uniform temperature and lower noise levels in homes and commercial properties, builders turn to rigid polyurethane and polyisocyanurate foam. These foams are effective insulation materials that can be used in roof and wall insulation, insulated windows, doors and air barrier sealants.

![]() Thermoplastic Polyurethane (TPU)

Thermoplastic Polyurethane (TPU)

Thermoplastic polyurethane (TPU) offers a myriad of physical property combinations and processing applications. It is highly elastic, flexible and resistant to abrasion, impact and weather. TPUs can be colored or fabricated in a wide variety of methods and their use can increase a product's overall durability.

![]() Reaction Injection Molding (RIM)

Reaction Injection Molding (RIM)

Car bumpers, electrical housing panels and computer and telecommunication equipment enclosures are some of the parts produced with polyurethanes using reaction injection molding (RIM). Adding design flexibility, the polyurethane RIM process produces parts that are usually not achievable using typical injection molding processes, such as thick- and thin-walled parts, encapsulated inners and foamed cores. In addition to high strength and low weight, polyurethane RIM parts can exhibit heat resistance, thermal insulation, dimensional stability and a high level of dynamic properties. Automotive, construction, appliance, furniture and recreation and sporting goods are a few of the markets and applications using RIM technology.

![]() In Addition To the aforementioned applications for polyurethane,

In Addition To the aforementioned applications for polyurethane,

it is also an integral part of the following industry applications, in one form or another:

![]() Product Binders

Product Binders ![]() Waterborne Polyurethane Dispersions (PUDs)

Waterborne Polyurethane Dispersions (PUDs)

![]() Apparel

Apparel

![]() Appliances

Appliances

![]() Automotive

Automotive

![]() Marine

Marine

Over 55 Years of Experience in the Cast Urethane Industry

Elastomer Specialties, Inc. 2210 S Highway 69, Wagoner, OK 74467 Ph: 918-485-0276 | 800-786-4244 Fax: 918-485-0253