Custom Cast & Molded Urethane Products

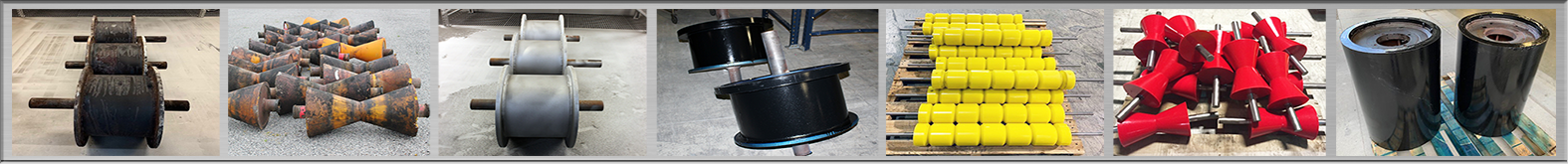

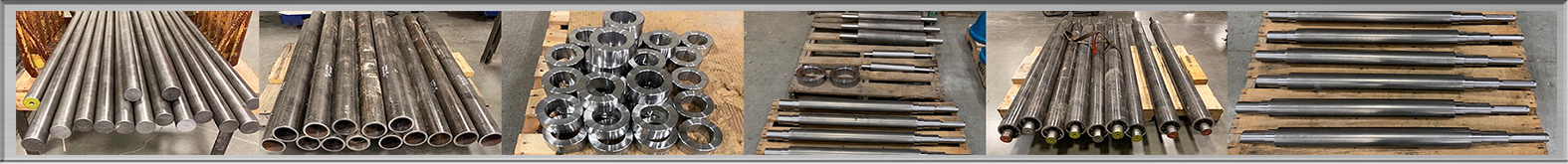

In recent years the Wind Power Industry has exploded and thousands of wind turbines are being installed both nationally and worldwide. The rollers that support these huge diameter tower sections are extremely heavy and very expensive. The life expectancy of the polyurethane on these steel hubs (axles) is short lived but even shorter when rubber is used.

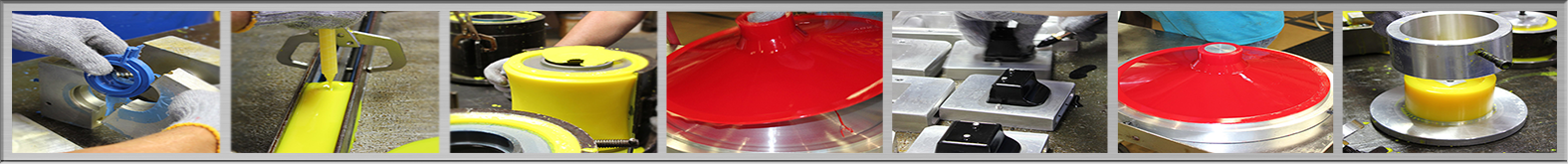

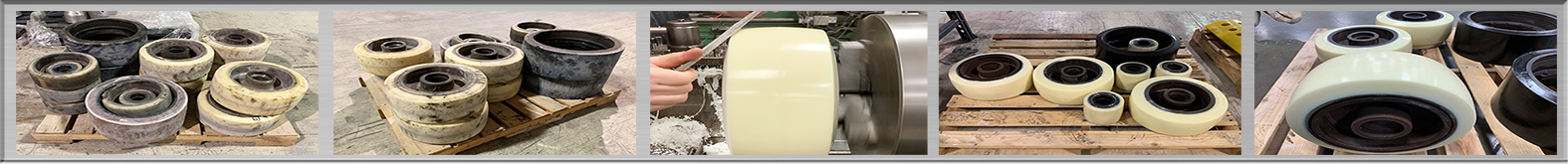

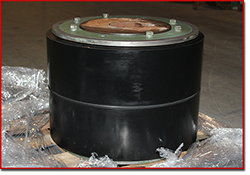

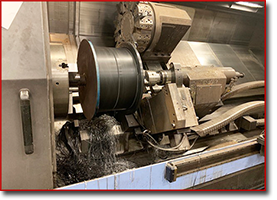

The replacement of an entire turning roller is very costly. ESI has a developed a proven system to completely remove the old molded rubber or polyurethane from the steel axle, then properly prepare and prime the steel surface. Once that process is complete, Elastomer Specialties recasts the axle with a specifically formulated, highly durable polyurethane material. This unique polyurethane elastomer is engineered to stand up against the high heat and abrasion generated as the roller turns the wind turbine tower sections.

Our unique refurbishing technology is guaranteed to save our customers both time and money.

Roller refurbishing has been a major expertise of ESI for over 45 years. Our system gives our customers the most durable elastomer product available. When our refurbished rollers are returned to our customers, they are more abrasive and chemical resistant and have longer lasting performance than before.

When you send us your worn down turning rollers or any roller for that matter, we remove the worn rubber or urethane using our unique process, prepare the surface by grit-blasting and priming, then send it to our casting department. The end result is our refurbished rollers will meet or exceed most manufacturers' strict specifications.

You need an experienced company with a rock solid reputation that will help you take your product to market with a competitive edge!

Call us today for a production quote!

Innovators of Molded Polyurethane and Hybrid Polyurea Technology!

Contact ESI @ 800-786-4244 or 918-485-0276

Elastomer Specialties, Inc. 2210 S Highway 69, Wagoner, OK 74467 Ph: 918-485-0276 | 800-786-4244 Fax: 918-485-0253